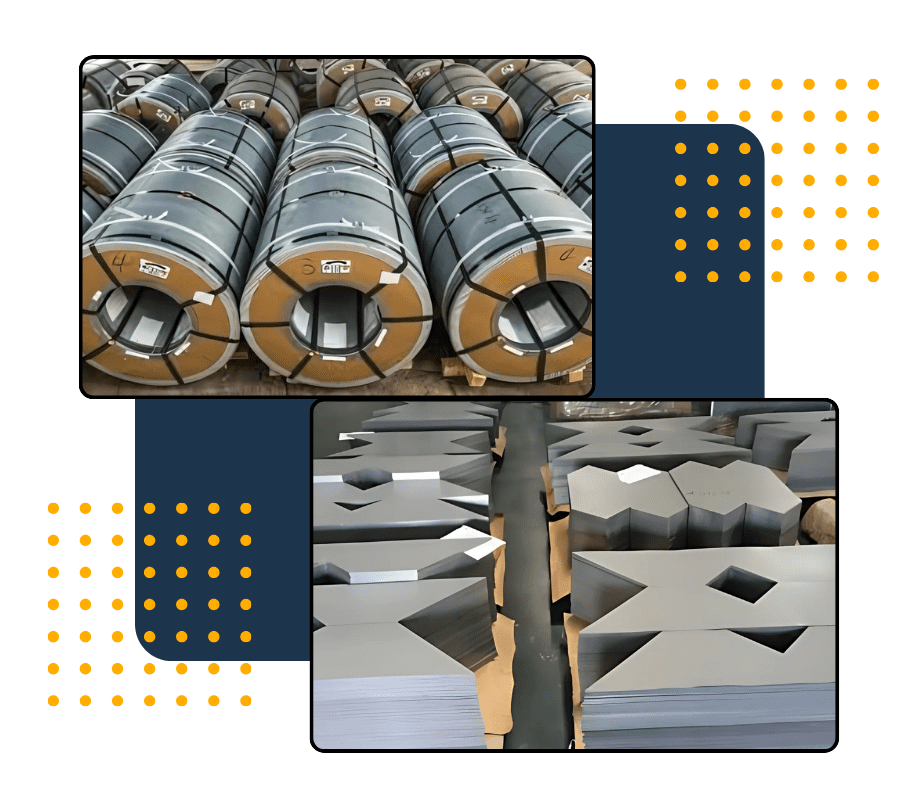

AMM Power Pvt. Ltd. is a trusted supplier of high-quality CRGO (Cold Rolled Grain Oriented) lamination for power and distribution transformers in India. We source premium-grade CRGO materials from globally renowned manufacturers in Japan, USA, Korea, Germany, and Russia, ensuring superior performance and efficiency in transformer cores.

AMM Power Pvt Ltd manufacturers, exporters and suppliers have own manufacturing and core slitting plant for CRGO lamination in India. We use different material & make as per customer required no-load losses, thickness, flux density and other technical specifications.

We supply CRGO lamination to many reputed transformer manufacturers worldwide.

Purpose of Laminations

Laminations are used in transformer cores to minimize energy losses caused by eddy currents. Eddy currents are loops of electric current induced within the core by the alternating magnetic field, which generate heat and waste energy. By using thin, insulated layers of magnetic material instead of a solid block, the formation of these currents is significantly reduced, thereby improving the transformer’s efficiency.

Technical Specifications

Characteristics of CRGO electrical steel are affected by impurities, grain size, grain orientation and surface insulation. Even minor stresses, burrs, edge cambers or bends can increase core losses and magnetizing current significantly. Jay Bee Laminations Limited has the facilities to ensure proper handling and stress free processing of the material.

| General physical and mechanical properties of CRGO steel | |

|---|---|

| Density | 7.65 g/cm3 |

| Thickness of sheet | 0.23 – 0.35 mm |

| Silicon content | 3-4 % |

| Yield Point (relative to rolling direction) | 0 degrees • 330 N/mm2 90 degrees • 355 N/mm2 |

| Tensile strength | 0 degrees • 348 N/mm2 90 degrees • 412 N/mm2 |

| Elongation | 0 degrees • 11% 90 degrees • 31% |

| Number of bends | 0 degrees • 21 90 degrees • 15 |

| Hardness (Hv) | 204 |

| Stacking factor | 95-98% |

Grade classification of Electrical Steel

| Electrical Steel | Grade (BIS nomenclature) | Grade (Conventional nomenclature) | Thickness (mm) | Max Core loss (W/kg) 50 Hz | |

|---|---|---|---|---|---|

| @1.5T | @1.7T | ||||

| CRGO | 20HP70D | 20-70 | 0.20 | 0.52 | 0.70 |

| 23HP75D | 23-75 | 0.23 | 0.55 | 0.75 | |

| 23HP85D | 23ZDKH | 0.23 | 0.60 | 0.85 | |

| 23HP90 | 23M0-H | 0.23 | 0.64 | 0.90 | |

| 23HP100 | M3 (Low loss) | 0.23 | 0.68 | 1.00 | |

| 23CG110 | M3 | 0.23 | 0.70 | 1.10 | |

| 27HP90D | 27ZDKH | 0.27 | 0.66 | 0.90 | |

| 27HP100 | 27M0-H | 0.27 | 0.70 | 1.00 | |

| 27HP110 | M4 (Low loss) | 0.27 | 0.78 | 1.10 | |

| 27CG120 | M4 | 0.27 | 0.85 | 1.20 | |

| 30CG130 | M5 | 0.30 | 0.90 | 1.30 | |

| CRNGO | 35C230 | 0.35 | 2.30 | ||

| 50C470 | 0.50 | 4.70 | |||

| 50C600 | 0.50 | 6.00 | |||

Tolerance chart for dimensions of CRGO laminations (as per IS 3024)

| Attribute | Attribute Range/Value | Tolerance |

|---|---|---|

| Width | 0 – 100 mm 100 mm – 230 mm 230 mm – 400 mm 400 mm – 750 mm | +0.00 / -0.15 mm +0.00 / -0.20 mm +0.00 / -0.30 mm +0.00 / -0.50 mm |

| Length | 0 – 350 mm 350 mm – 1,000 mm 1,000 mm – 2,000 mm 2,000 mm – 3,000 mm 3,000 mm – 4,000 mm | +0.00 / -0.30 mm +0.00 / -0.60 mm +0.00 / -1.00 mm +0.00 / -1.50 mm +0.00 / -2.00 mm |

| Thickness | 0.23 – 0.27 mm 0.30 – 0.35 mm | +/- 0.025 mm +/- 0.030 mm |

| Mitering Angle | 45 degrees | +/- 5 minutes |

| Burr Height | 0.18 – 0.23 mm 0.23 – 0.30 mm 0.30 – 0.35 mm | 10 microns 15 microns 20 microns |

| Wave Factor | Material width > 150mm, Flatness deviation | Max. 1.5% of width |

| Edge Camber | Material width > 150mm | Max. 0.8 mm for length of 1.5m |

| Hole Dimension | Up to 34 mm | +/- 0.15 mm |