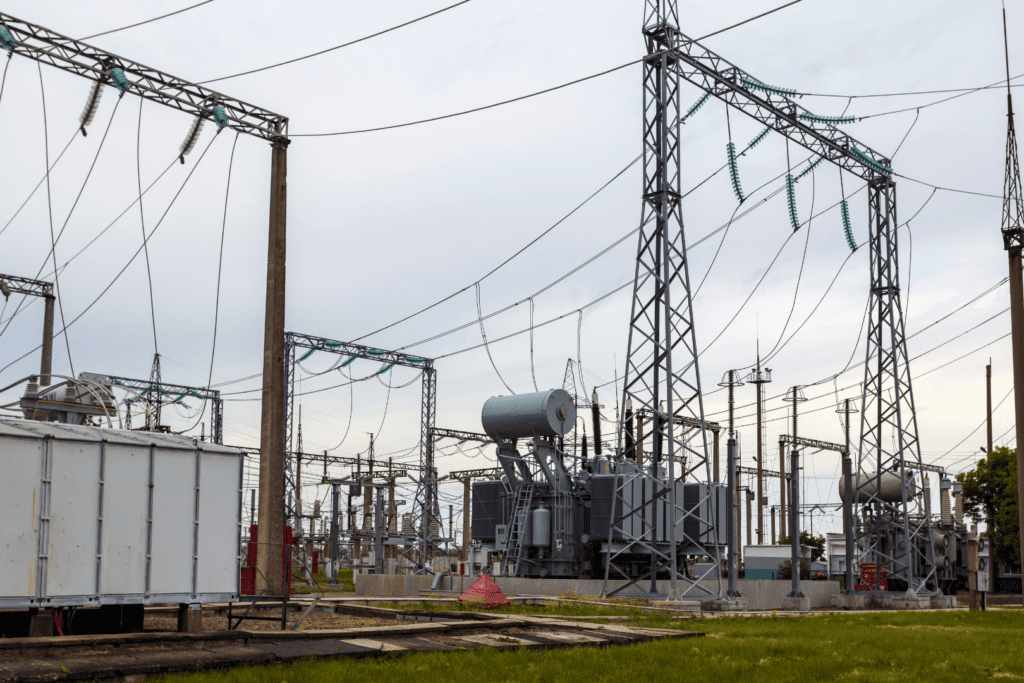

AMM Power Pvt Ltd, a leading transformer manufacturer, uses Cold Rolled Grain Oriented (CRGO) steel to produce highly efficient transformers for industrial and commercial applications, as transformer efficiency directly impacts energy distribution networks, with core lamination quality being a key performance factor.

What is CRGO Lamination?

CRGO, or Cold Rolled Grain Oriented steel, is a specialized silicon steel that aligns grains in a single direction, minimizing energy loss due to hysteresis and eddy currents, making it suitable for transformer cores.

Why CRGO Lamination is Crucial for Transformers

- Reduced Core Losses:

The use of CRGO significantly lowers core losses (hysteresis and eddy current losses), improving the energy efficiency of transformers. - High Magnetic Permeability: CRGO steel allows magnetic fields to pass through easily, enhancing performance.

- Improved Reliability and Longevity: With reduced heat generation and loss, transformers with CRGO cores last longer and operate more reliably.

- Compact Design: Enhanced magnetic properties allow for a more compact transformer design, saving on space and material costs.

- Cold Rolled Grain Oriented (CRGO) Steel is a crucial material used in transformer core manufacturing due to its excellent magnetic properties, which help reduce energy losses.

CRGO Lamination Process at AMM Power Pvt Ltd

AMM Power Pvt Ltd follows a meticulous and quality-controlled process for incorporating CRGO lamination into its transformers:

Applications of CRGO Laminated Transformers by AMM Power Pvt Ltd

Key Features of CRGO Lamination:

✅ Low Core Loss – Minimizes energy dissipation, improving transformer efficiency.

✅ High Magnetic Permeability – Enhances the transformer’s performance by reducing magnetizing current.

✅ Precision Cutting – Manufactured using CNC and laser cutting for accurate dimensions and reduced wastage.

✅ Thickness Range – Typically available in 0.23mm, 0.27mm, and 0.30mm thicknesses.

✅ Annealed for Stress Relief – Enhances grain orientation to optimize electromagnetic properties.

Common Applications:

Manufacturers & Suppliers of CRGO Laminations in India & Saudi Arabia:

- India: KRYFS Power Components, Jay Bee Laminations, Banmore Electricals, Posco Poggenamp.

- Saudi Arabia: Imported from global suppliers like AMREST Electricals Ltd.

FAQs

Q1. What is the difference between CRGO and non-CRGO lamination?

CRGO has aligned grain structure, offering much lower core loss than non-CRGO steel, which is randomly oriented.

Q2. Are CRGO laminated transformers more expensive?

Initially yes, but they offer long-term savings in energy efficiency and reduced operational costs.

Q3. Does AMM Power Pvt Ltd offer custom transformer designs?

Yes, AMM Power Pvt Ltd offers customized solutions tailored to specific customer needs.

Q4. How long does a CRGO transformer last?

With proper maintenance, CRGO laminated transformers can last over 25 years.

Leave a Reply