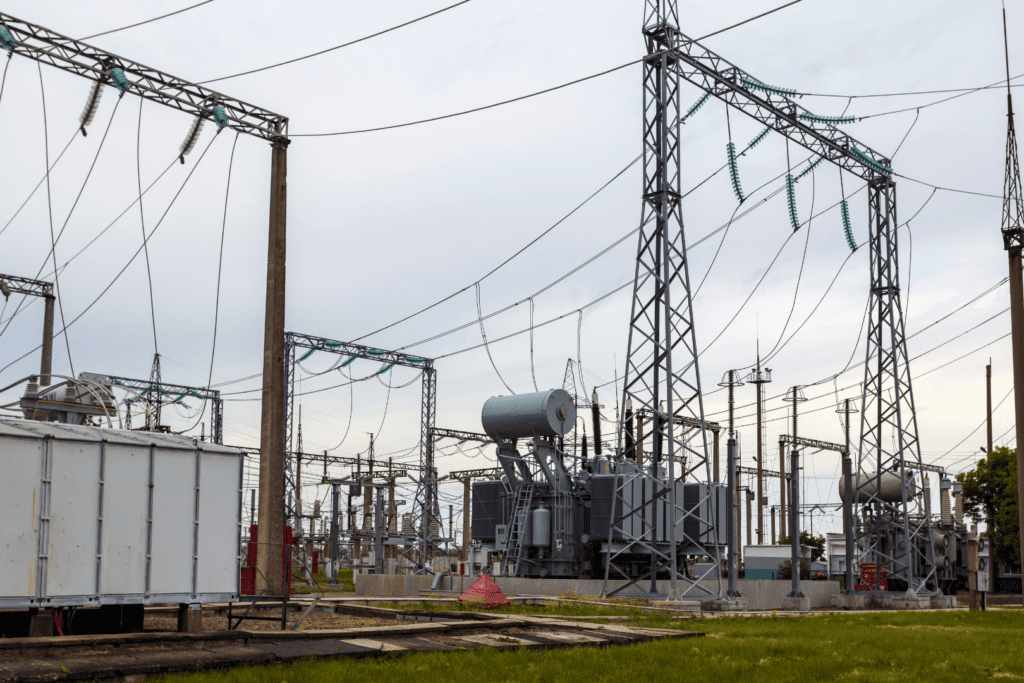

AMM Power PVT LTD, a leading manufacturer in India’s power and electrical sector, is known for its innovation, precision, and manufacturing excellence. Their CRGO laminations are crucial to the country’s transformers and industrial equipment, providing unmatched quality and performance. This article delves into the world of CRGO laminations, their importance in the electrical industry, and AMM Power’s reputation as a reliable CRGO lamination manufacturer in India.

What Are CRGO Laminations?

CRGO stands for Cold Rolled Grain Oriented steel, a type of electrical steel that’s specially processed to offer high magnetic permeability. These laminations are used in transformer cores to ensure minimal energy loss and optimal magnetic performance.

The material is processed to align the grain structure of the steel in the rolling direction, allowing it to efficiently carry magnetic flux. This makes it the preferred choice for core laminations in transformers, reactors, and other electrical appliances.

Why CRGO Laminations Are Critical in the Power Industry

AMM Power PVT LTD – A Trusted Name in CRGO Lamination Manufacturing

AMM Power PVT LTD, established in 2011, is a leading Indian electrical product manufacturer known for producing high-quality CRGO transformer core laminations that meet national and international standards, thanks to its advanced infrastructure and skilled workforce.

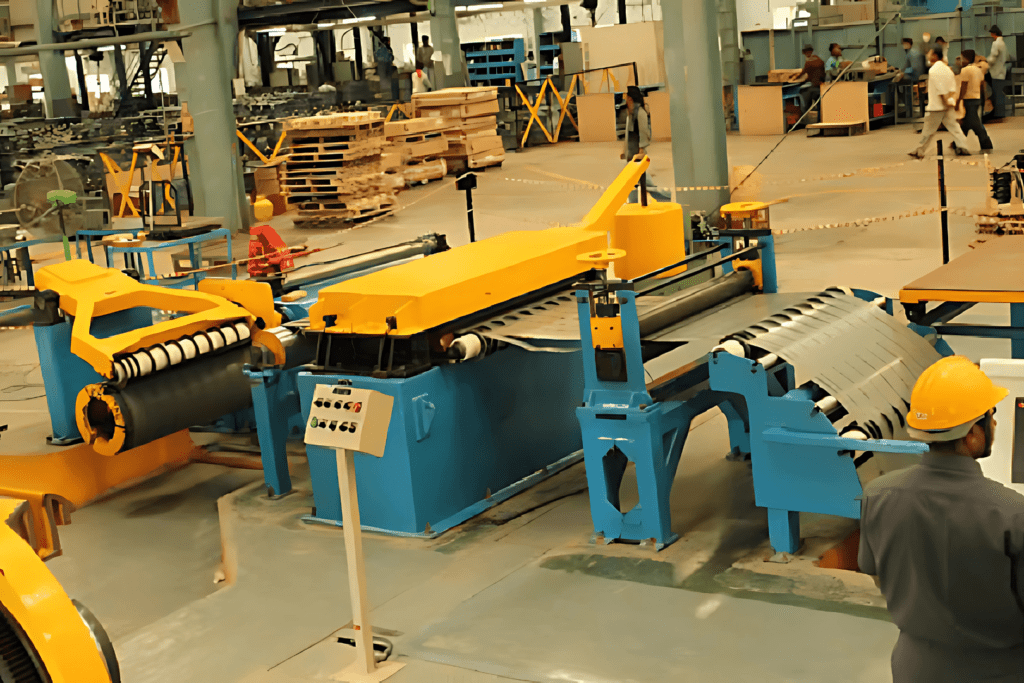

Advanced Manufacturing Capabilities

AMM Power operates with a focus on cutting-edge CNC machinery, ensuring high precision and minimal wastage. The company follows strict quality control protocols at every stage of production—from raw CRGO coil sourcing to final lamination output.

Manufacturing Process Features:

Leave a Reply